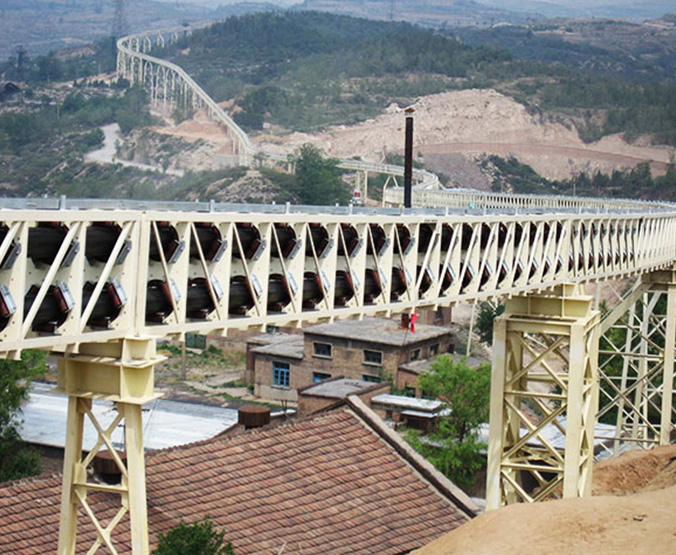

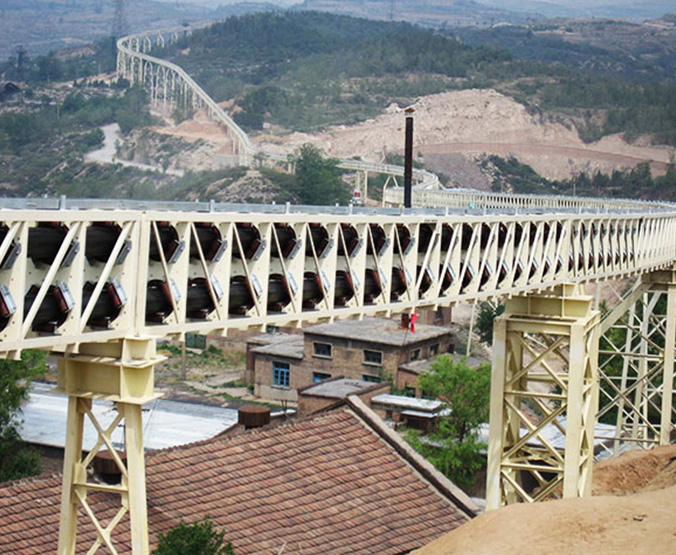

Tubular belt conveyor/tube conveyor/pipe conveyor is a transport equipme4nt used to roll the belt into a tube to pack the materials then transport them. Tubular belt conveyors are widely used in the power industry, coal industry, grain industry, mechanical industry, mining etc.

1.It takes smaller space: max incline angle is 30, minimum tuning radius is 45m, it can save 60% space compares to the standard belt conveyor;

2.No system limitations and decreased transportation costs;

3.The closed transfer protects the material.

According to the customers’ needs, the tubu belt conveyor machine can realize the two -way transport material, that is, the upper tape transports the material from the tail to the head, and the lower tape transports the material from the head to the tail. This product is suitable for continuous transportation of scattered materials under various complex terrain conditions. The density of transporting material is generally 0.5 ~ 2.5T/m3, and a normal pipe conveyor belt is used. The working environment temperature is -25 ℃ ~ + 40 ℃. Special requirements such as cold -resistant, waterproof, anti -corrosion, explosion -proof, and flame retardant, the working environment temperature can reach -35 ° C ~ + 110 ° C. This product can be widely used in power transportation systems such as electric power, building materials, chemicals, mines, metallurgy, docks, ports, coal, food and other industries. The tube tube is a new type of band conveyor that is wrapped in a roller arranged by the cross section to the edges into a round tube -shaped to transport the material. It has the characteristics of cleaning and environmental protection, the transportation line can be flexibly arranged along the space curve, large conveying inclination, and the long -term single transportation distance of the single -single transportation under the conditions of complex terrain. The transportation stations), convenient installation and maintenance, safe and reliable operation, tape is not easy to run off. Our company can conduct on -site topography, system design, equipment manufacturing, installation, commissioning, after -sales service and other general contracting on site to provide users with full -process nanny -type services.

| d tube/mm | Width(mm) | speed(m/s) | Pulley diameter(mm) | Roller diameter(mm) | Max transportation(dmEx/mm) |

| 150 | 600 | 1.8 1.0 | 500-630 | 50 63.5 | 30-50 |

| 1.25 1.6 | 76 89 | ||||

| 2.0 2.5 | 108 133 | ||||

| 3.15 4.0 | 159 194 | ||||

| 4.5 5.0 | |||||

| 200 | 750 | 630-800 | 50-70 | ||

| 250 | 1000 | 630-800 | 70-90 | ||

| 300 | 1100 | 800-1000 | 90-100 | ||

| 350 | 1300 | 1000-1250 | 100-120 | ||

| 400 | 1600 | 1250-1400 | 120-150 | ||

| 500 | 1800 | 1250-1400 | 150-200 | ||

| 600 | 2200 | 1400-1600 | 200-250 | ||

| 700 | 2550 | 1600-1800 | 250-300 | ||

| 850 | 3100 | 300-400 |